FZSONICK manufactures and sales batteries for industrial applications dedicated both to backup solutions and to energy storage systems as well as to sustainable mobility solutions. There are OEM, ODM, Self Patent. What is a sodium sulfur battery? Sodium Nickel Chloride batteries.

Typical cell operating temperature varies between 2°C and 3°C. The battery ’s safe chemistry assures it has zero. These are separated by a ceramic aluminum oxide separator. It is the only dedicated EV battery in production in the world today. C (4°F) and uses molten sodium tetrachloroaluminate ( NaAlCl ), which has a melting point of 1°C (3°F), as the electrolyte.

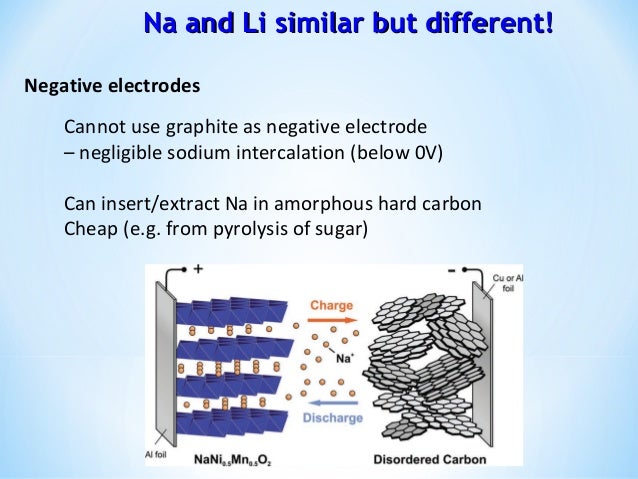

The negative electrode is molten sodium. The positive electrode is nickel in the discharged state and nickel chloride in the charged state. Jump to navigation Jump to search. The report provides a basic overview of the industry including its definition, applications and manufacturing technology.

High Temperature Battery operating at over 270°C. High energy density (times higher than Lead acid) Large cells (up to 500Ah) possible. Tolerant of short circuits. Both forms of nickel electrode are insoluble in their liquid states and a sodium conducting beta alumina ceramic is used as the separator.

Zebra Batteries Characteristics. NaCl) at the negative electrode and nickel (Ni) as the positive electrode. High power, high capacity cells suitable for electric traction applications.

Fully recyclable within existing industries for the production of stainless steel and road paving. Basic Construction of a ZEBRA cell. The sodium-ion battery explained. The prototype developed by the team at Stanford contains a sodium-based cathode, the pole of the battery that stores electrons. The more efficient this process is, the better the battery works.

Firstly, the report provides a basic overview of the industry including its definition, applications and manufacturing technology. Japan), Exide Industries Limited (India), F. M SpA (Italy), Fujian Quanzhou Dahua Battery Co. MW project dedicated to sodium nickel chloride technology, falls within the scope of the large safety, network protection and national power grid modernization plan organized by Terna. Dropping the battery from a height of 9. For more than years, MES-DEA has sold ZEBRA batteries for use in electric vehicles. The other major use for nickel is in batteries and fuel cells.

A variety of battery designs, including those exploiting nickel -cadmium, nickel -iron, nickel -hydrogen, and nickel -metal-hydride chemistry, use nickel as a cathode. In alkaline fuel cells, nickel foam or nickel mesh are used as gas diffusion electrodes. They have advantages for electric vehicles. This report studies sales. We manufacture and export Nickel (II) chloride , or nickelous chloride or just nickel chloride which is a high melting, paramagnetic yellow solid commonly found in the laboratory.

Packaging Size: kg, kg. Alibaba offers 7Nickel Chloride For Electroplating Industry Suppliers , and Nickel Chloride For Electroplating Industry Manufacturers , Distributors, Factories, Companies. Find high quality Nickel Chloride For Electroplating Industry Suppliers on Alibaba.

The modern rechargeable sodium -sulfur is known as sodium - nickel - chloride battery or ZEBRA, so-called after the Zeolite Battery Research Africa project. Europe’s first generation of electric vehicles. Ammonium Bicarbonate. B - Battery Acid to Butyric Acid. C - Calcium Chloride to Copper Sulphate.

Caustic Potash Flake. Lithium ion batteries will remain the top choice for personal electronics and to power electric vehicles into the foreseeable future.

Žádné komentáře:

Okomentovat

Poznámka: Komentáře mohou přidávat pouze členové tohoto blogu.